over three decades of quality work

Our journey started in 1990 designing and building machinery for mining industry. Four years later we founded SC Proumin SRL, a Romanian private company who designs and manufactures complete sets of tooling for large and complex metallic parts. We accumulated since then vast experience and an impressive portfolio comprising services and products for customers from a large and diverse field of industrial activities.

Our activity takes place on an area of approximately 20,000 m2, of which production areas 5,200 m2, divided into four production sections.

With customers and contractors spread all across the globe we are proud to have an international mission

THE INDUSTRIES WE PROUDLY SERVE

MINING & DRILLING

We are a traditional partner of mining companies, offering since the beginning the best solutions in the supply of external and underground mining equipment.

Due to the reorientation of the market, at the request of partners, we have expanded the work and equipment for drilling of tunnels.

metallurgical

We produce parts and components for milling and rolling plants (roller tables, conveyors, transfer cars, elevators, transfer lines, shears, etc.) and customized metallic components, equipment and machine tools, based on customer specifications.

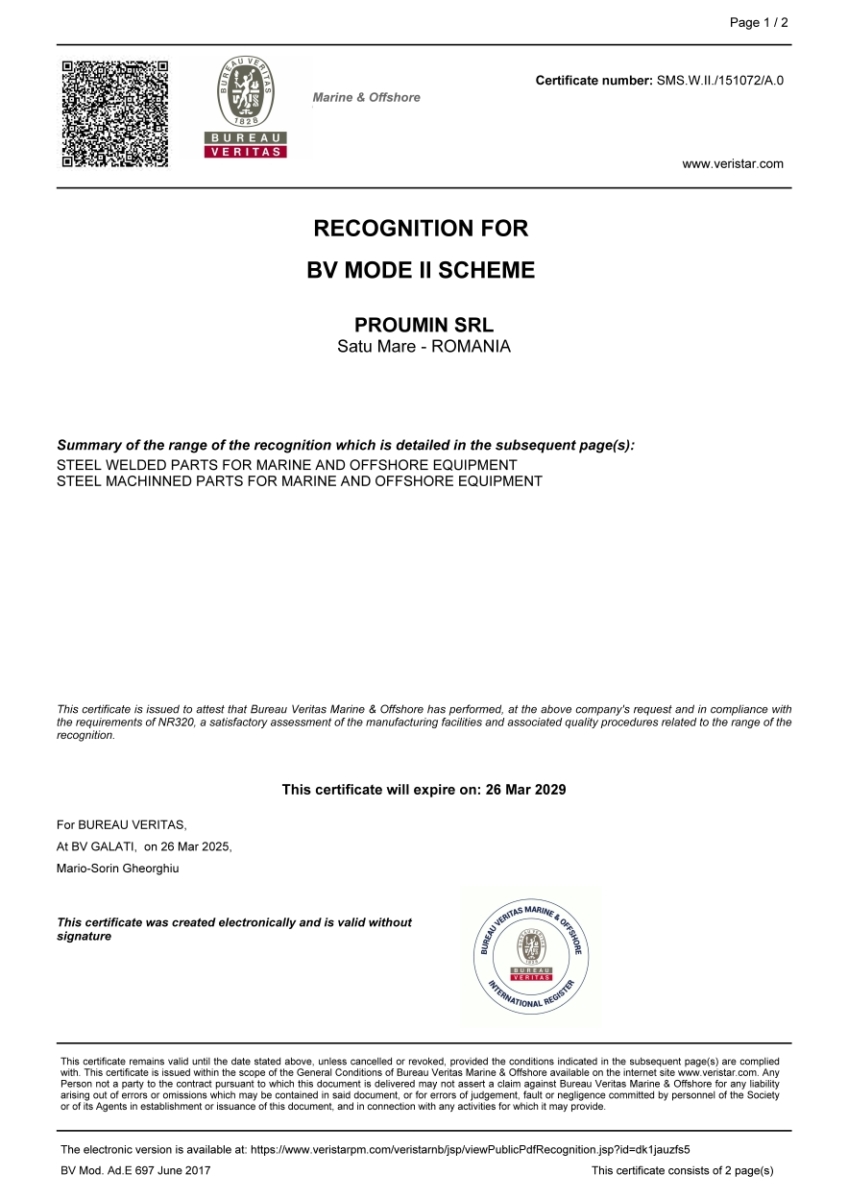

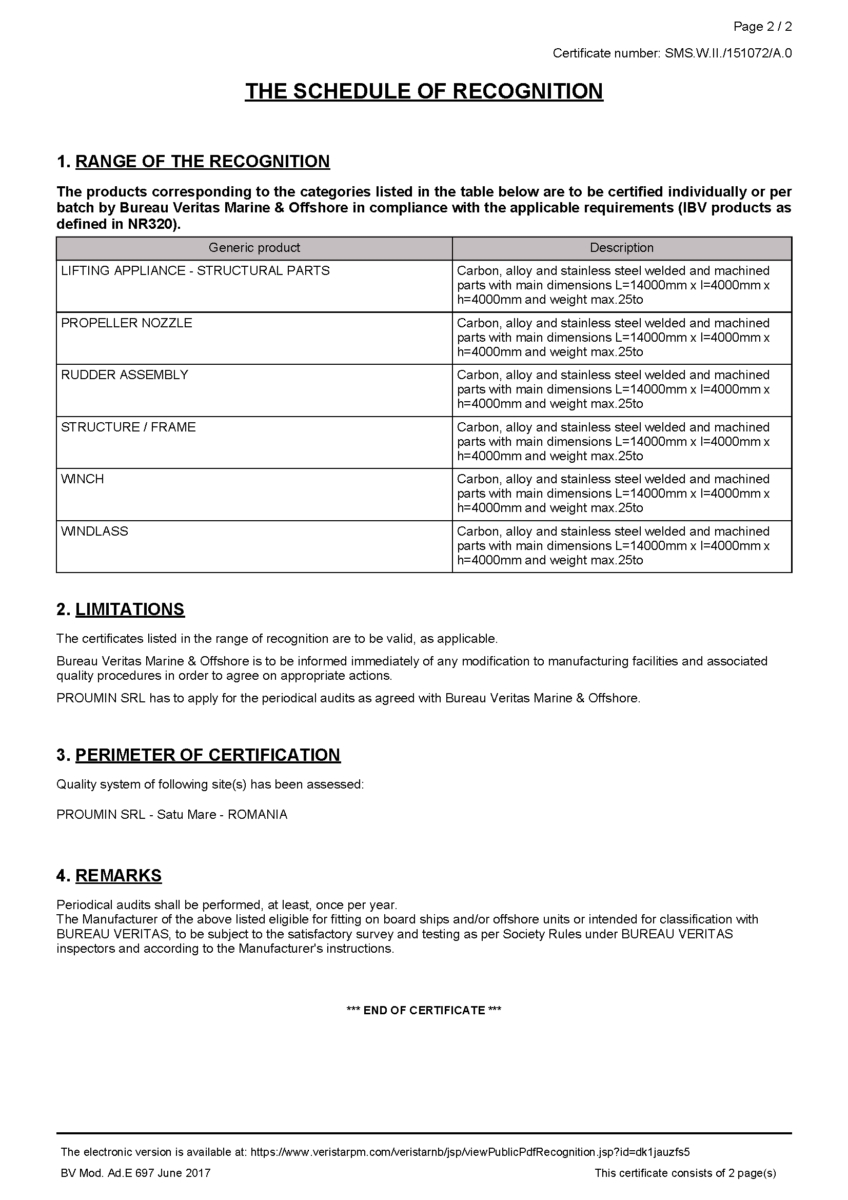

naval & offshore

We have the ability to execute equipments larger than 10 ml gauge, with weight up to 25000 kg.

renewable / nuclear energy

We are producing poles, parts for windmills, rotors, shafts and, on demand, other parts.

automotive & aerospace

Combined with a project-oriented organizational approach, our creativity and technical skills mean we can be efficiently involved in the design and production of high-tech equipment for large-scale infrastructure projects.

We are involved in complete sets of tooling manufacturing for metallic, aluminum and composite parts.

recycling

Design solutions, advice and support for the commissioning of equipment add value in this area but also large parts for crushers, presses, or compressing equipment can be ordered.

The most widely used equipment in this field is the conveyor belts and sorting strips built by Proumin including the design phase.

petrol industy

Proumin offers a wide range of equipment for the petrol industry and gas supply, including spare parts.

The most widely used equipment in this field is the conveyor belts and sorting strips built by Proumin including the design phase.

Since 1990 PROUMIN has grown and developed continuously. At the various stages we have gone through, we have accumulated the experience and know-how we use today to offer solutions dedicated to each individual customer.

EQUIPMENT

Boring and Milling Machine Type Emtech HBM-130

Column transverse travel (X axis)11000 mm

Headstock vertical travel (Y axis)4000mm

Ram travel (W axis)1150mm

Ram size380x460mm

Spindle travel (Z axis)800mm

Total Z+W travel1950mm

Rapid feeds on X, Y, Z axis15m/min

Min. working feed speeds of axis X, Y, Z0,5 mm/min

Max. working feed speeds of axis X, Y, Z3000mm/min

Positioning error for axis X, Y, Z0,022 mm/2m

Spindle diameter130mm

SpindletaperISO-50

Spindle power30kW

Spindle speed 2500rpm

Fix table:2000mmx6000 mm(Max. load 10T/sqm)

Rotative table 2000×2500 (Max. load30t)

Boring and Milling MachineType EmtechHBM-130

Column transverse travel (X axis) 7200mm

Headstock vertical travel (Y axis) 2800mm

Ram travel (W axis) 1150mm

Ram size 380x460mm

Spindle travel (Z axis) 800mm

Total Z+W travel 1950mm

Rapid feeds on X, Y, Z axis15m/min

Min. working feed speeds of axis X, Y, Z 0,5mm/min

Max. working feed speeds of axis X, Y, Z 3000mm/min

Positioning error for axis X, Y, Z 0,022mm/2m

Spindle diameter130mm

SpindletaperISO-50

Spindle power 30kW

Spindle speed 3000rpm

Horizontal Lathe DoosanInfracore Puma400XLC

Swing over bed-770mm

Swing over saddle-590mm

Recom. turning diameter-305 [380] mm

Max. turning diameter-550mm

Max. turninglength-3150mm

Bar workingdiameter-90mm

Travel distance X-axis – 362mm

Z-axis – 3150mm

Milling and Boring CenterDoosan InfracoreDBC130-II

X-axis –3000mm

Y-axis –2000mm

Z-axis –1600mm

W-axis – 700mm

Distance from spindle nose to table top – 0~2000mm

Distance from spindle nose to table center – 700~2300mm

Rapid Traverse Rate X, Y, Z-axis – 10m/min

Cutting feedrate X, Y, Z-axis – 1~4000mm/min

Milling and Boring MachineJohnford BMC110

X AxisTravel-2000mm

Y AxisTravel-1800mm

Z AxisTravel-1600mm

W Axis Travel-550mm Boring Spindle Diameter -Ø110mm

Spindle Center to Table Top -0~1800mm

Spindle Nose to Table Center -550~2150mm

Spindle Speed(rpm)-5~3000

3D Measuring Arm - Faro Prime2.4m

6-axis configuration,

Repeatability – 0.024mm

Accuracy – ± 0.034mm

Bluetooth®technology

Internal counterbalancing

Including various ball diameters, custom extensions and optional touch sensitive probe

Temperature & overload sensors Located in each joint, they allow the arm to “feel” and react to thermal variations and improper handling for maximum accuracy.

Vertical Machining CenterDoosan DNM400-II

X-axis-762mm

Y-axis-435mm

Z-axis-510mm

Distance from spindle nose to table top -150-660 mm

Distance from spindle nose to column-512mm

Max. Cutting feedrate -15000 m/min

Table size -920*435 mm

Max. Spindle speed -8000 {12000} {8000} r/min

Vertical Machining Centers - Kytamura Mycenter1/485

X-axis:19.1 “

Y-axis:13“

Z-axis:16“

RPM:13000 rpm

Taper:BT-35

Control:CNC(Fanuc M)

Table Size: 14″ x 31″

Doosan Lynx 220LLathe

Max. Turning Diameter -320mm

Max. Turning Length – 500 Class mm

Standard Chuck Size – 6/8 inch

Bar Working Diameter – 45 / 51 / 65 mm

Max. Spindle Speed – 6000 / 5000 / 4000 r/min

Max. Spindle Motor Power –15kw

NC System – FANUC / SIEMENS

Machining Capability -Standards, M, MS, Y, SY

CNC ERMAKSAN POWERBEND 6100 x 500 TON PRESS BRAKE

Length of bending 6000mm

Force press 500To

Windows-style operating system.

2D and 3D programming

17” LCD touch-screen

Automatic tool selection from library for bending parts

Error message display

PLATE ROLLS AKYAPAK AHS30/32-40

Working Length 3100mm

Max thickness 40mm

Top roll 460 mm

Bottom roll 420mm

Length 6300mm

Height 2600mm

Width 2300mm

Blasting Instalation - BlastWizard C200E/M

Capacity-Metallic abrasive : 800kg

Working pressure6.0 – 10.0 bar

Maximum pressure12.0 bar

Air connection1 ¼ “

Blast hose connection1 or 1 ¼“

Volume – 200 l

Diameter-609mm

Height-1450 mm

Weight-150 kg

Air consumption6 bar, nozzle 9,5 mm

6 bar, nozzle 8 mm6,0 m 3 / min 4,0 m 3 / min

Graco Merkur Airless sprayer paint

Band Saw Bianco 420 SA DSMS

Table height:830mm

Saw band length:3270 x27 x 0,9 mm

Cutting diameter:280mm

Capacity 45°rectangular:260 x 200mm

Capacity 90°rectangular:420 x 180mm

Capacity 45degrees: round:200-260mm

Capacity 90 degrees: square:250 x 250mm

Esab Falcon FXA 3000 CNC Gas& Plasma

Cut area 2000mmx 6000mm

2 off automatic oxypropane gas torches (Cutting upto 150mm mild steel with auto ignition and heightcontrol)

1 off ESAB ESP150 plasma system (upto 25mm mild steel)

Roscamat 400 PneumaticTapping Machine

Radial arm with a360º turningradius

Pneumatic motor with anair unit

Modularsystem

7 output speeds (90,170, 300, 550, 750, 1050 and 2100 rpm)

Capacity M2-M24(M27)

Radius 1100 mm.Height: 680 + 140mm.

Bridge Crane Bonfanti25t/10t/8t/5t

Types 25t/10t/8t/5t

Working capacity – 25000kg 2pcs

Working capacity – 10000kg 1pcs

Working capacity – 8000kg 3pcs

Working capacity – 5000kg 1pcs Bridge:

Span – 14460mm

Wheel base – 3500mm

Wheel diameter – 315mm

Rail width – 60mm

Trolley:

Span –2100mm

Wheel base –1400mm

Wheel diameter -250mm

Rail width -50mm

AUTOMATIC STRAIGHT-CUTTING BANDSAWS HBP RANGE HBP530

Cutting range:

90° round – 530

90° square B x H – 520 x 520

90° flat B x H – 530 x 520

Feed length single stroke: 500

We deliver quality

at the highest standards.